How PVC (Vinyl) Roofs Resist Fire

PVC roofing membranes are inherently fire resistant. Thermoplastic PVC is a naturally fire-resistant polymer, making this cool roofing material slow to catch or spread fire – and self-extinguishing when the source of heat or flame is removed. PVC roofs have passed both FM and UL fire testing. To see for yourself, view a dramatic fire test conducted by Southwest Research Institute’s Fire Technology Department.

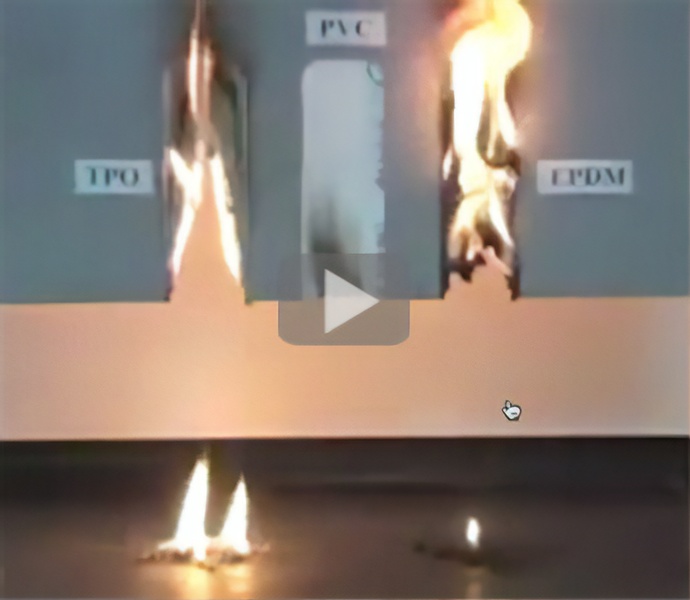

The test compares the behavior of three common commercial single-ply roofing materials – vinyl or PVC, TPO and EPDM – after they are ignited by a Bunsen burner flame.

In the test, the PVC roofing sample self-extinguishes in seconds (13 in one, 12 in the other) after the flame source is removed, while the other two samples continue to burn for between 3 and 6 minutes apiece before they are completely consumed. Read the full fire-resistant roofing report.

PVC roofs have passed applicable FM and UL tests for Class A and B roof assemblies for high and low slope roof applications. UL and FM ratings are specific to individual roofing membrane manufacturers. Check with each company’s technical department for company-specific ratings.

LEARN MORE ABOUT THE FIRE PERFORMANCE OF PVC MEMBRANE ROOFING MATERIAL TODAY

Contact the Vinyl Roofing Division today for more information on the fire performance, cost effectiveness and sustainability of membrane roofing material.

Durability

PVC roofing membranes can stand up to some of the toughest stresses and have been proven to support and protect roofs throughout the world.

Learn more about this durable, high-performance low-slope roofing solution »

Sustainability

Roofs made of PVC roofing membrane contribute significantly to achieving two major objectives of green building programs – the reduction of both building cooling loads and the urban heat island effect.

See why PVC membranes are the sustainable choice among commercial roofing systems »

Aesthetics

PVC roofing membranes’ aesthetic qualities make them the choice for any roof design.

Find out why PVC is recommended for projects with aesthetic considerations here »