The Sustainability Benefits of PVC Roofs

Long Service Life

Reduces Peak Electricity Demand

Recyclability/

Capability

Comprised of Renewable Raw Materials

Reduces Temperature of Urban Heat Islands

Reduces Building Cooling Load

Reduces Smog and Greenhouse Gases

Lighter-Colored PVC Roofs Reflect More of the Sun’s Rays

Why PVC (Vinyl) is the Sustainable Roofing Solution

Protecting Your Building While Protecting the Earth

PVC has an inherent advantage over many other roofing materials when it comes to recycling.

According to the U.S. Environmental Protection Agency, construction and demolition waste from buildings totals an estimated 332 billion pounds annually. Reroofing generates tremendous quantities of material that can and should be diverted from the waste stream. The vinyl roofing industry is committed to combining existing post-consumer recycling technologies with logistical expertise to limit its contribution to these numbers. In 2021, the member manufacturers of CFFA’s Vinyl Roofing Division recycled a combined 758 thousand pounds of membranes at the end of their service lives.

Learn More About Pre-Consumer and Post-Consumer Recycling

Project Profiles

Learn more about specific examples of sustainable roofing projects from across America.

Athens Community Center

Athens, Ohio

Bishop Elementary School

Ypsilanti, Michigan

Girdler Elementary School

Girdler, Kentucky

Target Store

Kyle, Texas

Maybury Material Handling

Longmeadow, Massachusetts

Dairy Queen

Milford, Massachusetts

Close Harbor Seafood

Plantsville, Connecticut

Warm Springs Condominium Development

Fremont, California

Park on Main Project

Norman, Oklahoma

Why Architects and Specifiers Should Choose PVC Roofs

PVC membranes are often recommended for commercial roofing projects with cosmetic features. With this material, aesthetics need not take a back seat to other critical building envelope considerations.

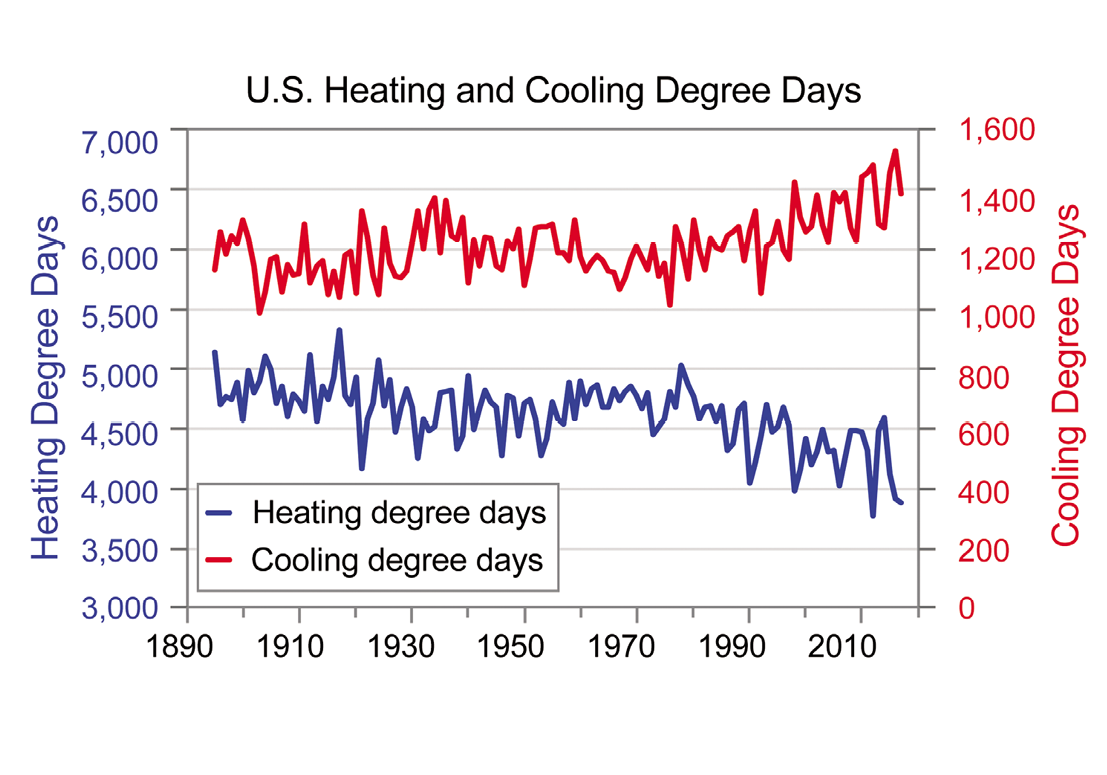

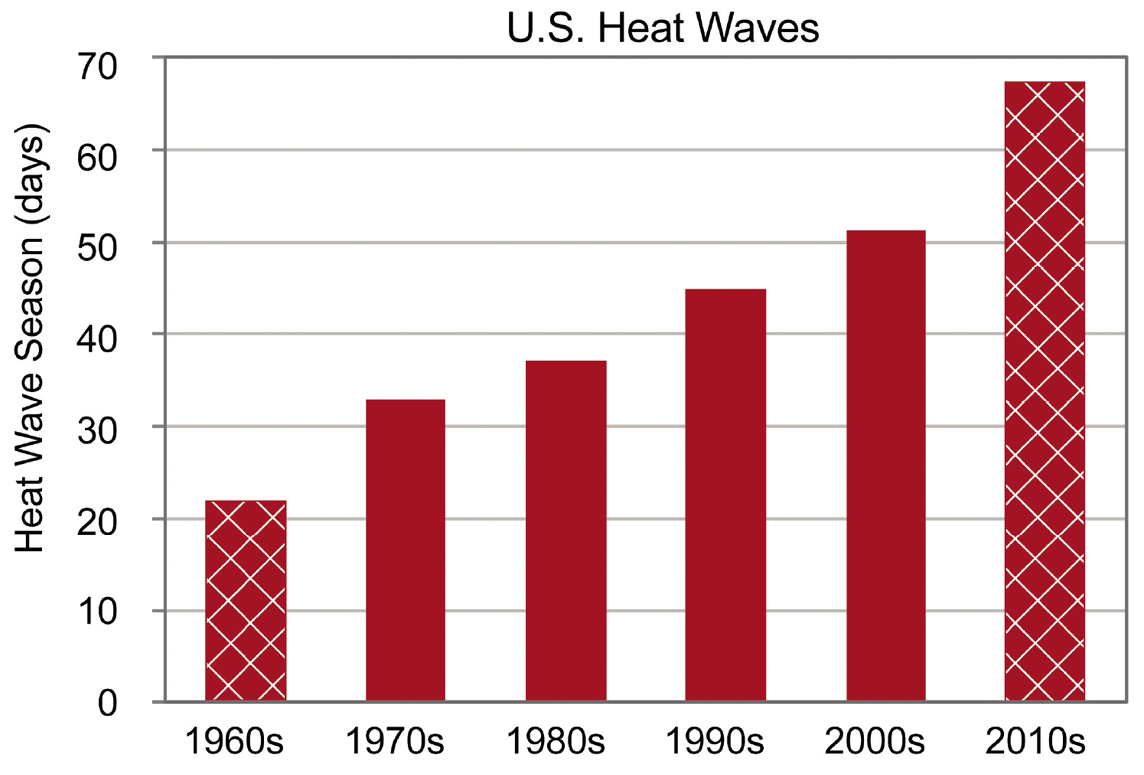

Why We Need Cool Roofs for a Warming World

Rising temperatures and prolonged heat waves are fast becoming the key challenges for our cities and urbanized areas. A white PVC commercial roof can reflect 80% or more of the sun’s rays and emit at least 70% of the solar radiation a building absorbs. Regardless of climate, when the sun beats down, a cool roof will counteract the effects of heat islands formed by heat-absorbing surfaces – dark roofs, concrete, pavement and parking lots – to keep ambient temperatures low.

Accurately Measuring the Sustainability of Building Products

There are shortcomings with the way carbon data is reported and they should not be used for direct comparisons of products. What oft-used cradle-to-gate calculations do not take into account are the longevity of the finished product, and the embodied carbon that would result from multiple installations with an overall building’s service life, as well as its contributions to reductions in energy and waste consumption over decades.

Continuing Education Courses

References & News

Additional Resources

Why We Need Cool Roofs for a Warming World ![]() [8.7 MB]

[8.7 MB]

Sika Sarnafil’s Roof Recycling Program Proves Win-win for Business Owners & Environment

Elementary School Roof Scores an A+ For Sustainability

End-of-Service Life Recycling of Thermoplastic Roof Assemblies ![]() [6.4 MB]

[6.4 MB]

Zero Waste Roofing ![]() [1.7 MB]

[1.7 MB]

The Facts on PVC and the Environment ![]() [1.5 MB]

[1.5 MB]

Sustainability of Thermoplastic Vinyl Roofing Membrane Systems ![]() [515 KB]

[515 KB]

Trading Off Cool Roofs for Insulation

Aging and Weathering of Cool Roofing Membrane ![]() [184 KB]

[184 KB]

Mitigating New York City’s Heat Island with Urban Forestry, Living Roofs and Light Surfaces ![]() [1.9 MB]

[1.9 MB]

Radiative Forcing and Temperature Response to Changes in Urban Albedos and Associated CO

Durability

PVC roofing membranes can stand up to some of the toughest stresses and have been proven to support and protect roofs throughout the world.

Learn more about this durable, high-performance low-slope roofing solution »

Aesthetics

PVC roofing membranes’ aesthetic qualities make them the choice for any roof design.

Find out why PVC is recommended for projects with aesthetic considerations here »