Post-consumer recycling of PVC roofing membranes.

Post-consumer recycling is key to a circular system.

Pathway to Circularity promotes a truly circular system, advancing postconsumer recycling of mechanically fastened and induction welded PVC (vinyl) roofing so materials live on well beyond their first use. It invites the entire value chain—manufacturers, contractors, architects, and building owners—to participate in a regenerative roofing cycle. The goal is to make the recycling of existing PVC roofing as straightforward and cost-effective as possible, while demonstrating the long-term value of sustainable design.

PVC roofing is easy to recycle. It can simply be removed from the roof system in a process called skinning and transported to various recyclers. This eliminates the need for the landfilling of the membrane and reduces the cost of roof disposal.

While skinning adds some cost to the overall reroofing project, some of that cost can be offset with elimination of landfill fees and increased building value helping to achieve or maintain green building certifications. PVC roof recycling can also help companies achieve sustainability goals related to carbon reductions while adding to their environmental story and sustainability message.

- Triple bottom line and ESG benefits could include greater value for a building when green building certifications are awarded.

- Customers and stakeholders are looking to the vinyl value chain for recycling leadership, initiatives, and achievements.

- It is the right thing to do and relatively inexpensive.

Post-Consumer Recycling Facts and Figures

Closed-loop and open-loop cycles.

Closed-Loop Cycle

In a closed-loop cycle, PVC roofing is recycled and used to make new PVC roofing membranes, roof walkways and accessories. Because of its polymer structure, PVC can be recycled and reused over and over again.

Open-Loop Cycle

In an open-loop cycle, PVC roofing is recycled and used to make products other than roofing. These products often include flooring, landscape expansion joints, and other products.

Typical Steps for Recycling PVC: Post-Consumer

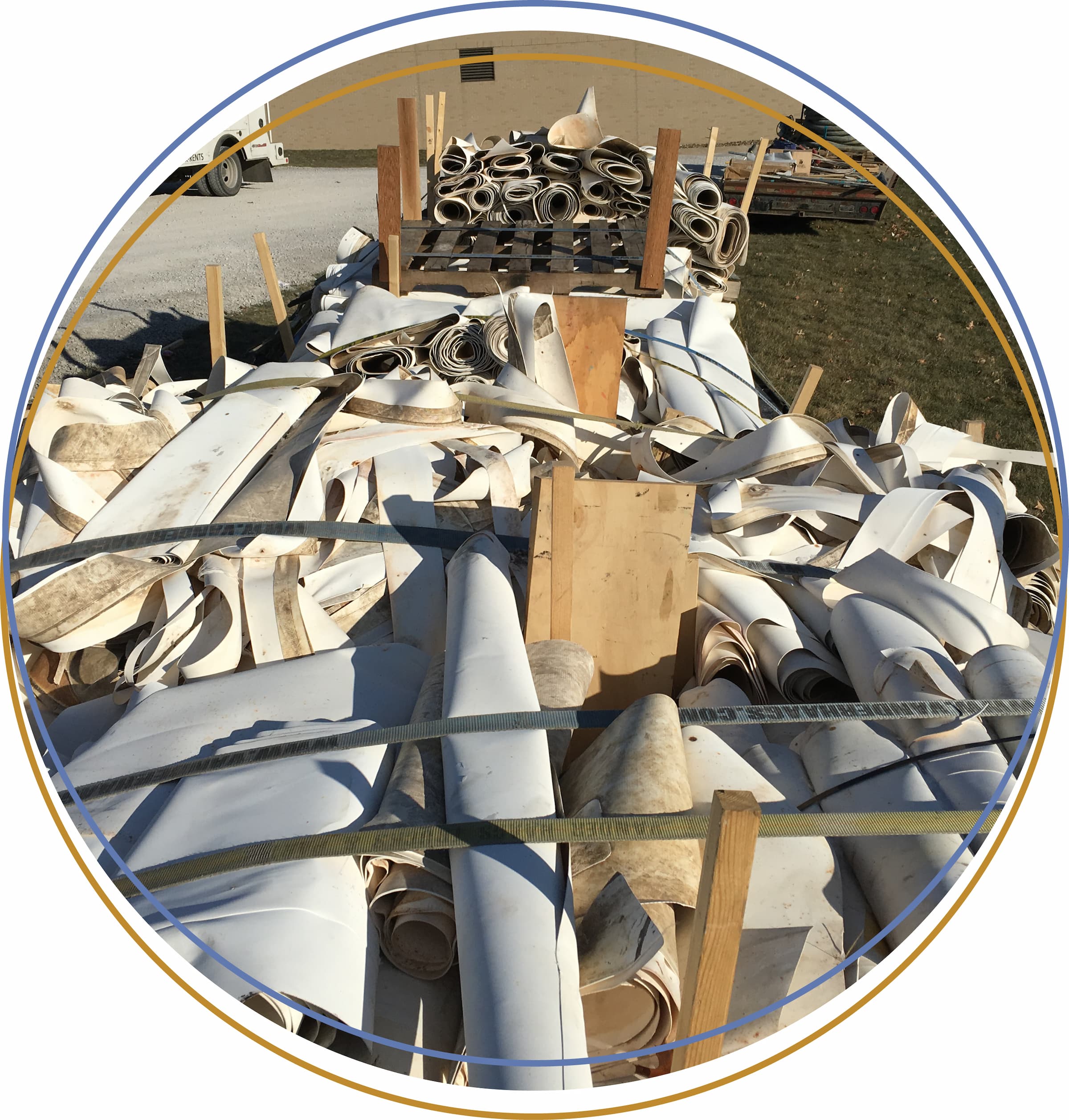

Slice the existing PVC Membrane into manageable size (approximately 3’ x 100’).

Roll up membrane.

If needed, tack weld to hold in place.

Put rolls on a 4-wheel dolly or other method to transport material to edge of roof.

Alternatively place rolls of existing membrane onto pallets and securely strap using metal bands, or place rolls of existing membrane into industrial bags.

Fill constructed gaylord boxes full of old PVC Roof membrane at rooftop or maximize what can safely be put on pallets or into industrial bags.

Lower gaylord constructed boxes to ground or other packaging/bundles.

Ready for pick up to recycler!

Arrange with recycler to pick up prepared packages/bundles of PVC roof membrane and load onto flat bed.

Roof Recycling Video

PVC (vinyl) roofing membranes are highly sustainable due to their ability to be recycled and repurposed into new products repeatedly, without significant loss of their key physical properties. In this video, we’ll walk you through the eight essential steps to successfully recycle PVC roofing membranes and reduce waste on your projects.

PVC Roof Recycling Guide Specifications & Suggested Bid Line Item

Recycling mechanically attached and induction welded PVC roof membranes is a sustainable option with proven results. If your project involves removing an existing PVC roof, it’s an ideal candidate for recycling into new roofing products and other vinyl products. We have provided this information to make it easier for specifiers to include in their re-roofing specifications. And we recommend roofing contractors include PVC recycling as a separate alternate bid line item, where appropriate, allowing building owners to evaluate costs alongside environmental benefits.

It is recommended that roofing contractors coordinate recycling opportunities directly with the PVC roofing manufacturer and watch this video for guidance on bundling and shipping the PVC membrane. Final project documentation should include confirmation of the amount of material diverted from landfills. All recycling steps must comply with OSHA and standard rooftop safety practices.

Download the PVC Roof Recycling Guide Specifications and Suggested Bid Line Item to include in your project bid documents.

Project Profiles

Learn more about specific examples of recycled roofing projects from across America.

Athens Community Center

Athens, Ohio

Bishop Elementary School

Ypsilanti, Michigan

Girdler Elementary School

Girdler, Kentucky

Target Store

Kyle, Texas

Park on Main Project

Norman, Oklahoma

Stakeholder Benefits

Discover how PVC single-ply roofing recycling creates value across the building lifecycle. These stakeholder-specific resources outline eligible roof systems, how to evaluate project feasibility, and the environmental and business benefits of diverting materials from landfill. Learn how recycling supports sustainability goals, responsible material management, and long-term performance.

Roofing Contractors

Building Owners & Facility Managers

Specifiers & Consultants

Reference Materials

Explore our reference materials to learn more about the benefits, performance, and sustainability of post-consumer recycled vinyl roofing from CFFA’s Vinyl Roofing Division.

Raising the Roof on Sustainability

The vinyl (PVC) roofing industry’s move to increase post-consumer recycling.

Opportunities for Recycling in Building Cycle Renovations

A Case Study of PVC Roofing Membranes

“Recycling Roofs” Podcast

Hear the story of PVC roof recycling on the National Roofing Contractors Association (NRCA) podcast “Stories of an Extraordinary Industry”!

FAQs

Roof Membrane Recycling-Frequently Asked Questions: Many people/stakeholders are unaware that a significant number of commercial roofs can be recycled at the end of their service life, rather than being discarded in landfills.

PVC (vinyl) single-ply roofing membranes have been recycled for 25 years now. In total, over 200 million pounds of PVC roof membrane have been recycled into new roofing and other long-lasting products. In 2024 alone, over 10 million square feet of PVC roofing membrane were taken back and recycled.

PVC roofing manufacturers are leading the way with commercial roof recycling. We hope that this document answers your questions or directs you to resources that can help you.

Disclaimer:

This is intended as a quick reference to answer frequently asked questions about roof recycling. The CFFA Vinyl Roofing Division members or Recycling Coordinators take no responsibility/liability for content. You should always check with your roofing contractor, roofing consultant, or roofing manufacturer of choice, and local code requirements for more specifics on how best to handle your reroofing project.